RESPONSIBLE SOURCING

G4-LA14, LA15, HR1, HR4, HR5, HR6, HR9, HR10, HR11, SO10, SO11

We are committed to working with our suppliers and other stakeholders so as to continue driving responsibility in our supply chain. Our Responsible Sourcing Program establishes expectation and accountability, and provides the resources and training of our associates, suppliers, and factory management. By reinforcing our internal programs and working with partners who drive progress in key matters industry-wide, we are able to make an even greater difference for those working within our supply chain.

Standards for Suppliers

Our belief in respect for the safety of all individuals and for the Company has always been the fundamental basis of our business. Applying this to the supply chain implies that our suppliers operate with social and environmental responsibility everywhere, so we are constantly encouraging them to commit to high standards of responsibility, that they meet sound requirements in audits, and that they conduct comprehensive evaluations. Our goal is to lead the entire supply chain with responsible sourcing practices. This goal can only be accomplished through constant and proactive work with our suppliers, aimed at raising supply standards and having a positive impact on supply chain practices. For this reason we have a manual -Standards for Suppliers- which outlines the minimum operating standards expected of our suppliers and their factories, as pertains to the ethical treatment of workers, environmental safety, and proper operating practices.

Suppliers meet these Standards by respecting all human rights and by creating ethical and sustainable supply chains. These Standards must be visibly displayed, in the language spoken by the employees, in common areas of all facilities that manufacture products for the Company and its affiliates. Standards for Suppliers are:

- Full compliance with all corresponding national and local laws and regulations, including those related to work, immigration, health, safety, and the environment.

- Zero tolerance for slavery, child labor and/or the hiring of minors, forced labor to pay debts and/or to pay guarantees. All labor must be voluntary.

- Grant days off for workers, and ensure that work schedules are neither excessive nor in violation of any and all labor legislation in force.

- Follow hiring practices that accurately verify -prior to hiring- the age of the worker as well as legal permission to work in the country in question. All labor terms and conditions, including hiring, payment, training, promotion, termination of the labor agreement, and retirement should be based on the capacity and will of the person to perform the work outlined.

- Payment of wages, overtime and fringe benefits to all workers pursuant to or in excess of, legal requirements or collective bargaining agreements, whichever of the two is greater.

- Respect for the right of workers to peacefully and legally assemble or join the unions of their choice or to engage in collective bargaining.

- Provide workers with a safe and healthy work environment. Suppliers should undertake the preventive measures needed to eliminate or properly manage any and all occupational hazards.

- Ensure compliance with environmental legislation by all manufacturing facilities, including laws governing waste disposal, gas emissions, discharges, hazardous materials, and hazardous waste disposal. Suppliers should verify that all materials and components have been obtained from authorized crops and that they comply with all international treaties and protocols, and local laws and regulations.

- Associates should not be offered gifts, gratuities or entertainment, as they are forbidden from accepting the same.

- No transactions with associates that could constitute conflict of interest.

- Zero toleration, permitting of, or participation in acts of bribery, corruption, or unethical practices either with public officials or persons from the private sector.

- Keep accurate records on all Company-related matters, as per standard accounting procedures such as the Financial Reporting Standards in Mexico (NIF) or the International Financial Information Standards (IFIS).

These standards are parallel to auditing standards used by us to measure the extent of compliance by suppliers of Private Labels. If a factory does not comply with our standards, corrective measures must be conducted to improve performance. If not, said supplier shall no longer be allowed to supply us with any merchandise.

We firmly believe that the voice of the workers plays a key role in driving health and safety throughout the entire supply chain. Therefore, within Responsible Sourcing we require that all facilities display the toll-free numbers, email address, and website where workers may anonymously report their concerns, and in their native language.

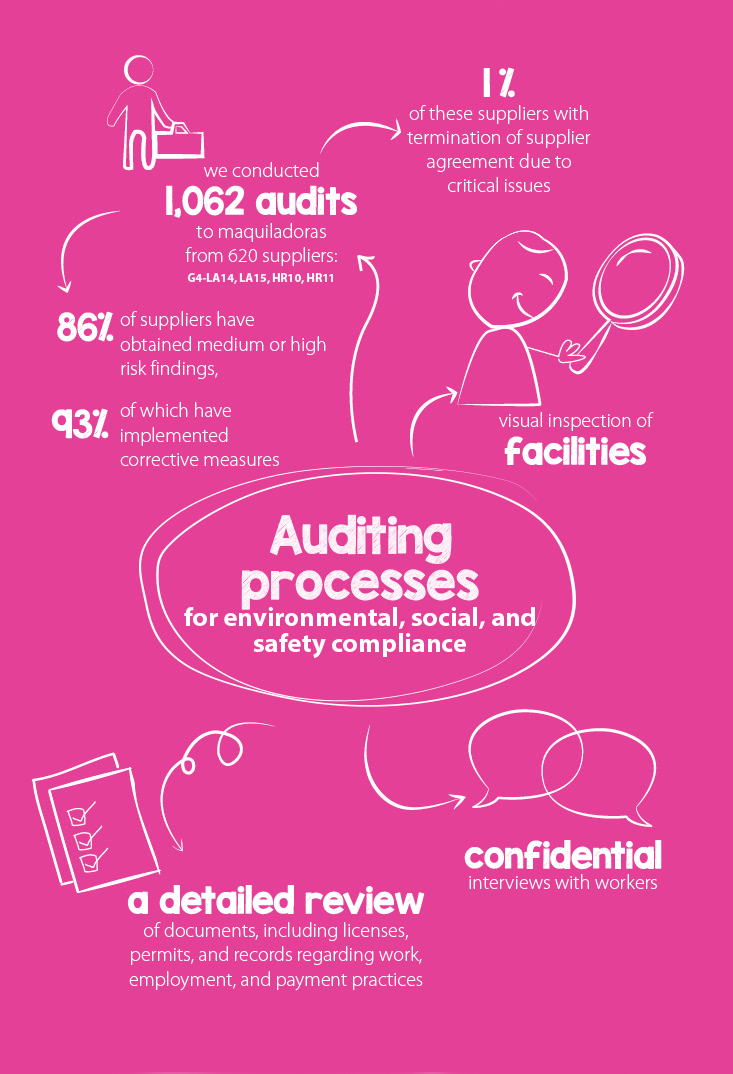

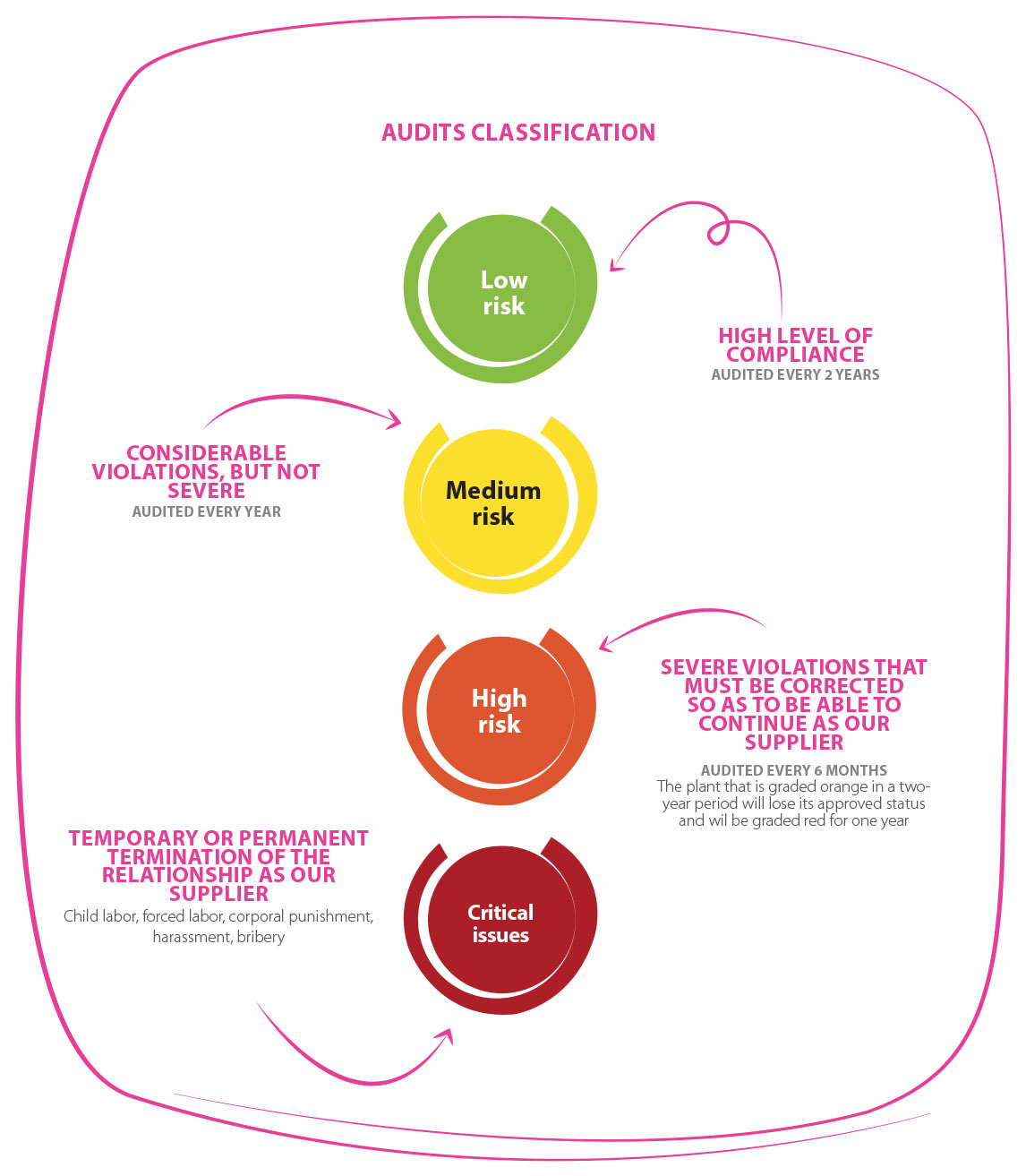

In general, the Responsible Sourcing audits are not announced, and they are conducted by third parties. The frequency of the repetition of an audit is based on the seriousness of previous findings. Results are assigned a color based on the seriousness of the issues found. We use this sort of classification to help with decision-making regarding suppliers and their factories. Audit results of factories are sent to each corresponding supplier using said facilities, and it is the responsibility of the suppliers to work with the factories so as to remedy the audit findings.

Risk management within the supply chain

In early 2015, we began to evolve our Responsible Sourcing Program, so as to center it around areas presenting the greatest potential risks for society, safety, and environmental compliance. The risk is evaluated based on data, and the risk factors included are those currently used by the World Bank Global Governance Indicators. We evaluate how the effectiveness and stability of the corresponding government, the rule of law, and corruption control affect the risk of non-compliance in the facilities of each country.

For risk management in the supply chain beyond our own audits, programs, and training, we are also developing alliances with other companies, governments, and NGOs to approach complex matters that no Company can accomplish alone. We believe this collaborative approach will foster greater impact on our supply chain and will make it even more effective.